0086-18861028088

Basket centrifuge machines are pivotal in various industries, including pharmaceuticals, food processing, and chemical manufacturing, due to their efficiency in separating solids from liquids. These machines leverage the principle of centrifugal force to achieve separation, a process that is both fascinating and complex. This article delves into the inner workings of basket centrifuge machines, exploring their design, operation, and the critical role they play in industrial processes.

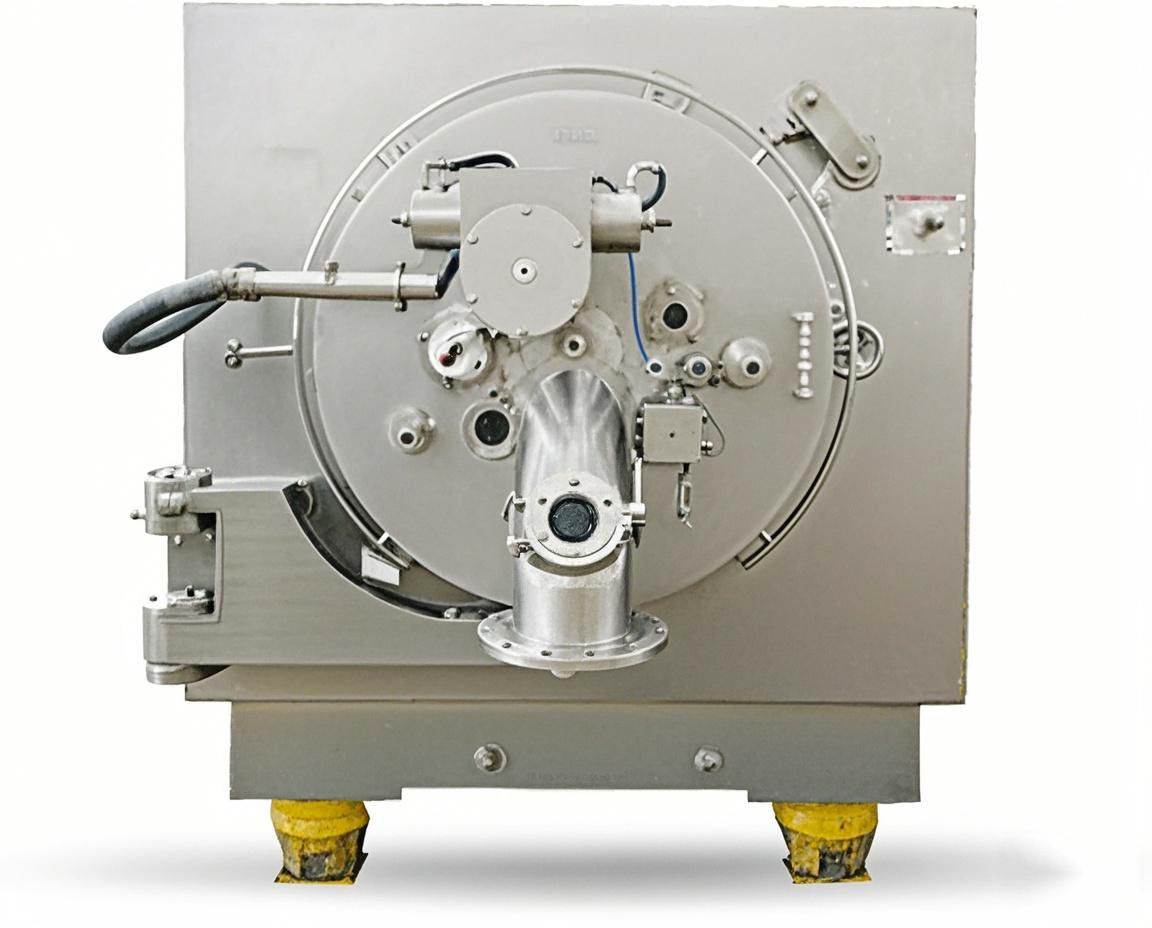

At its core, a basket centrifuge consists of a rotating drum or basket that spins at high speeds within a stationary housing. The basket is typically perforated and lined with a filter medium that allows liquid to pass through while retaining solids. The main components of a basket centrifuge include the basket, the drive mechanism, the housing, and the discharge system.

The drive mechanism is crucial as it provides the necessary force to spin the basket. It usually consists of an electric motor connected to the basket via a gearbox or directly through a spindle. The housing encloses the basket, ensuring safety and containment of the materials being processed. The discharge system, on the other hand, is designed to efficiently remove the separated solids and liquids from the machine. This system can vary significantly depending on the specific application and design of the centrifuge.

The operation of a basket centrifuge machine begins with the loading of the slurry, a mixture of solids and liquids, into the basket. Once the machine is started, the basket spins at a predetermined speed, generating centrifugal force. This force pushes the solids against the basket’s walls, while the liquid passes through the filter medium and exits the basket.

The efficiency of separation in a basket centrifuge is influenced by several factors, including the speed of rotation, the size and density of the particles, and the viscosity of the liquid. By adjusting these parameters, operators can optimize the separation process for different materials.

One of the key advantages of basket centrifuges is their ability to achieve high levels of dryness in the separated solids. This is particularly important in industries where moisture content is a critical factor, such as in the production of pharmaceuticals or in the processing of food products.

Basket centrifuges are versatile machines that can be used in a wide range of applications. In the pharmaceutical industry, this automatic horizontal centrifuge is used for the separation of crystalline drugs from their liquid medium. In the food industry, they are employed in the processing of edible oils, sugar, and other food products. Chemical manufacturers use basket centrifuges for the separation of chemical compounds and the recovery of precious metals.

The advantages of using basket centrifuges extend beyond their versatility. They are known for their high separation efficiency, which can significantly reduce processing times and increase productivity. Additionally, basket centrifuges are capable of handling a wide range of materials, including those that are sensitive to heat or prone to degradation. Their design also allows for easy cleaning and maintenance, making them a practical choice for industries with stringent hygiene standards.

Understanding the inner workings of basket centrifuge machines reveals the sophistication and efficiency of these devices. Through their clever design and operation, they play a crucial role in the separation processes of various industries, contributing to the production of high-quality products. As technology advances, it is likely that the capabilities of basket centrifuges will continue to expand, further cementing their position as essential tools in industrial processing.